Blog

Frequently Asked Questions

General

CDO answers your Asset Tracking Questions.

Q: Barcode vs RFID, how do I know which technology to use?

A: Barcode: Encodes digital data into a visual pattern (black lines and white spaces) that a barcode scanner can read. That encoded digital data from the barcode label transfers from the barcode scanner to a database. Barcode scanners read one label at a time and must be within line-of-sight of the scanner optics. The advantage of barcode technology is its accuracy and low price.

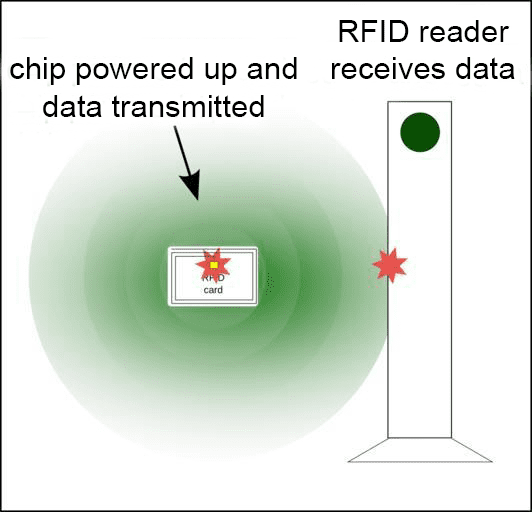

RFID (Radio-Frequency Identification): Uses digital data encoded in RFID tags and captured by a RFID reader via radio waves. That encoded digital data from the tag transfers from the RFID reader to a database. RFID has several advantages over systems that use barcode technology. The most notable is that RFID tag data can be read outside the line-of-sight. Barcodes must align with an optical scanner. RFID scanners can also read a large amount of RFID tags at one time. Barcode scanners can only read one label at a time.

Selecting the right technology depends on your application and environment. If you need high accuracy and your assets are in narrow storage aisles, the best technology choice is generally barcode. If you have hundreds of assets located in large storage aisles, rooms, or buildings, usually the best technology choice is RFID.

*Note: These are very simplified examples. You must understand assets, application, and environment to select the right technology solution.

Q: What is the best RFID tag to use for asset tracking?

A: There is no one best RFID tag. RFID tags come in hundreds of types, sizes, shapes, read range performance, and price. The better question is: what is the best RFID tag for my unique asset, unique application requirements, and unique environment? Identifying these is key to selecting the best RFID tag for your solution.

Q: What is the cost of RFID tags?

A: There is a great range in price of RFID tags. Based on volume, size, application, durability, RFID tags can cost as low as 10 cents or as much as $30+. Passive RFID tags are generally priced at the lower range and active tags that include a battery are at the upper range.

Q: What are the components of an Asset Tracking Solution?

A: The following include components of an Asset Tracking Solution:

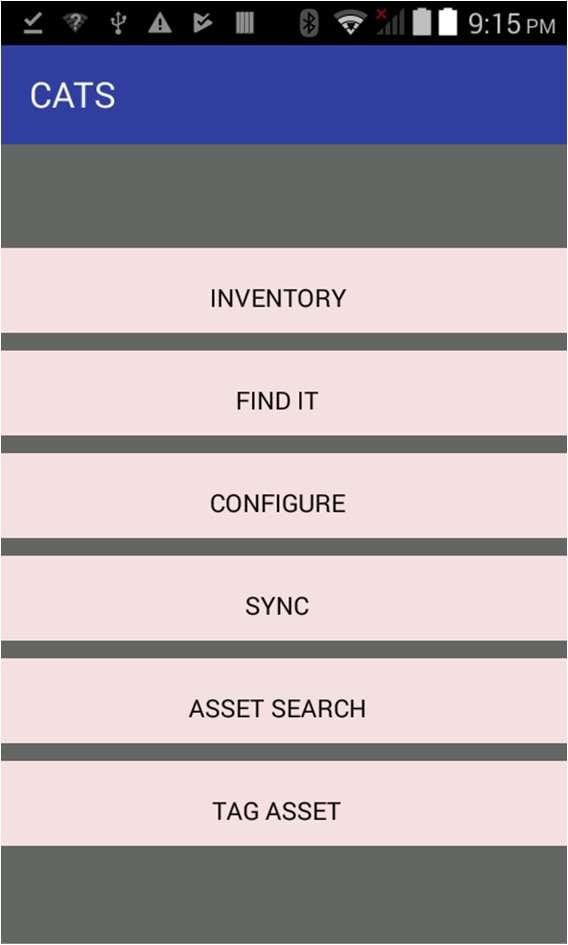

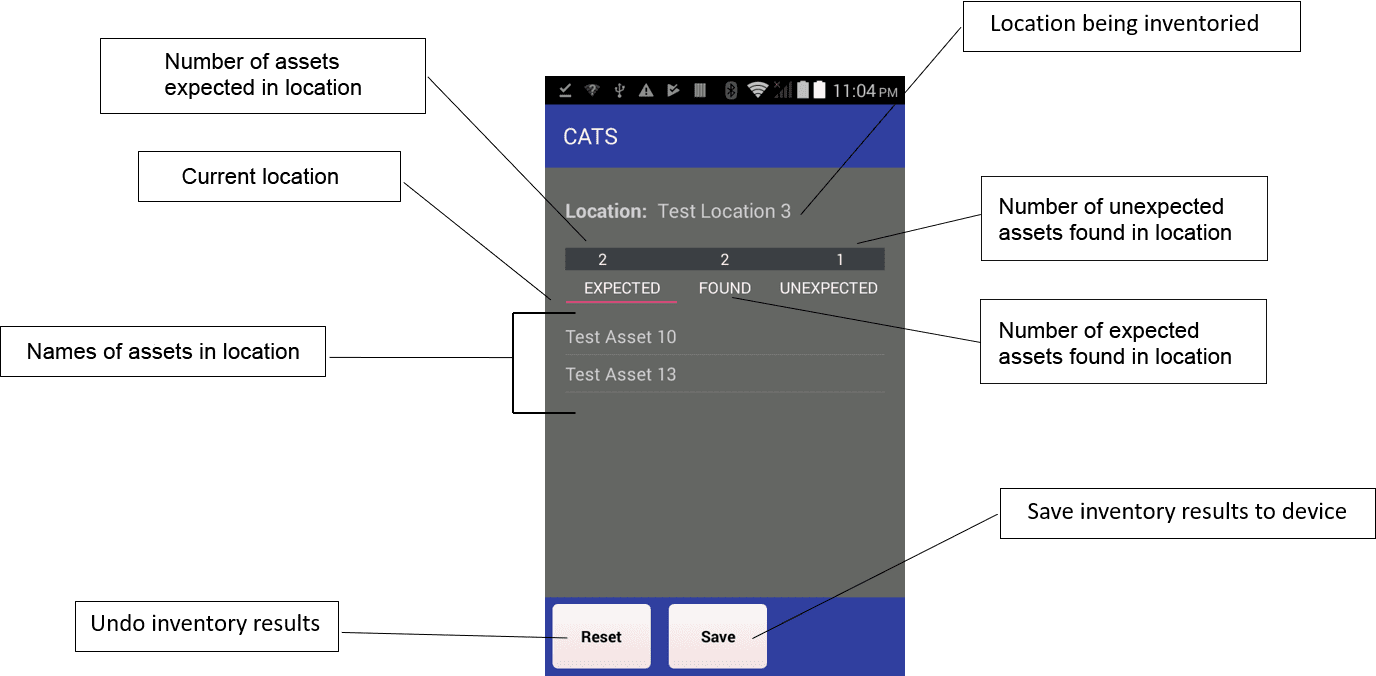

- Barcode or RFID labels and tags

- Barcode or RFID Mobile Scanners

- Barcode or RFID Fixed Reader/Antennas

- Asset Tracking Software: provides accurate asset visibility and location data from Barcode and RFID labels and tags.

*Note: It is important to speak with an experienced team to learn which technology will best fit your application and environment to solve your asset tracking and visibility issues.

Q: What other ERP, Inventory, or Warehouse software systems does your solution communicate?

A: The CDO solution can connect to any ERP system, inventory, or warehouse management systems. CDO can even communicate to home grown ERP systems. CDO software developers will talk to your team to identify the data that needs shared. Then develop an API (Application Programming Interface) or code to allow the software to communicate.

Business Case

Q: We have many issues tracking stuff, how do you know where to start?

A: All clients we work with have this problem. There are likely ten different issues that are causing problems in your operations. Keep it simple…what is the problem that is keeping you up at night? What is the problem that is impacting the most people? Ultimately, what is the problem that is costing you the most money? This is your Primary Issue.

We want to work on the Primary Issue because that will give us a significant Return on Investment (ROI) when we solve the issue. I’m sure you know, if an issue is only costing you $10K/year, your leadership team doesn’t get too excited. But if you have an issue that is costing you $100K/year then you’ll get your leadership’s attention.

Performing a Cost Analysis of your issues is a mandatory step to identify your Primary Issue. Completing that step will identify where to start.

Q: What is the cost of a typical Asset Tracking Solution?

A: The quick answer is $10,000 – $100,000. But, you’re asking the wrong question. The correct question is: what is the cost (daily, weekly, and yearly) when I misplace an asset, produce the wrong part, or ship to the wrong customer.

We understand the investment must provide value. The Return on Investment (ROI) must be greater than the price of the Asset Tracking Solution. The key is performing a COST Analysis of your issues or business operations. If your issues are costing $50,000/year, your Asset Tracking Solution needs to solve your issues for $50,000 or less so you have a positive ROI.

If you have more Asset Tracking questions or would like to further discuss your unique challenges, please schedule an appointment.