RFID vs. Barcodes: Can’t We Just Get Along?

With Radio Frequency Identification (RFID) gathering steam over the last several years, many people are asking if it is time to get rid of Barcodes and for RFID to take over. There are a multitude of benefits to using RFID, but there is still a time and place for Barcodes, and many applications for both technologies to coexist. So just how do these technologies help businesses do more with less, and when should you look at one application over the other?

How AIT helps businesses do more with less

Barcodes and RFID are Automatic Identification Technologies (AIT) that significantly improve processes by automating many of the manual aspects such as using tracking spreadsheets and physically going to search for misplaced assets. Some of the industries that have started implementing this technology include Healthcare, Manufacturing, and even Legal. In these industries, one tiny mistake can have a huge impact, so why take that chance if you can easily prevent it?

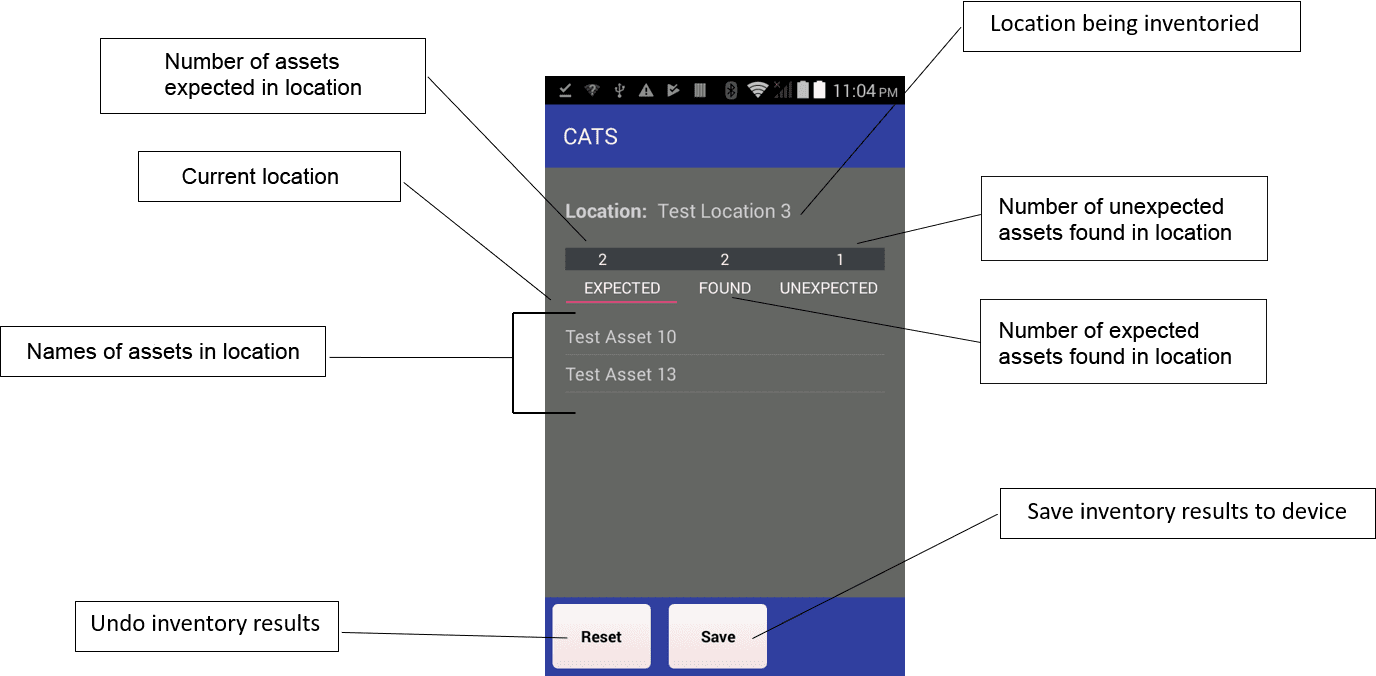

AIT helps answer the question “Where’s my stuff?” and gives better visibility of exactly what you have and where to find it. This will increase customer satisfaction and reduce costs. For industries heavy in compliance needs, a solution to track each piece of information is critical. Having a technology solution to automate processes will help ensure audit compliance.

Many companies face issues tracking their critical assets and need to have a buffer of items to use when something is misplaced. AIT lessens or eliminates that need for extra items. AIT can also integrate with other technologies and can automate processes that those systems aren’t able to handle. For example, manual entries into an ERP system can be entered automatically through a scanner. Many times, when something is entered manually into the system, it leaves the process open to human error and you are only able to upload the information once or twice a day at most. AIT solutions allow for frequent automatic data capture that provides real time information to your ERP systems. As a result, your ERP system is more accurate and up-to-date. When you have a fast-paced environment, you need a technology that can keep up.

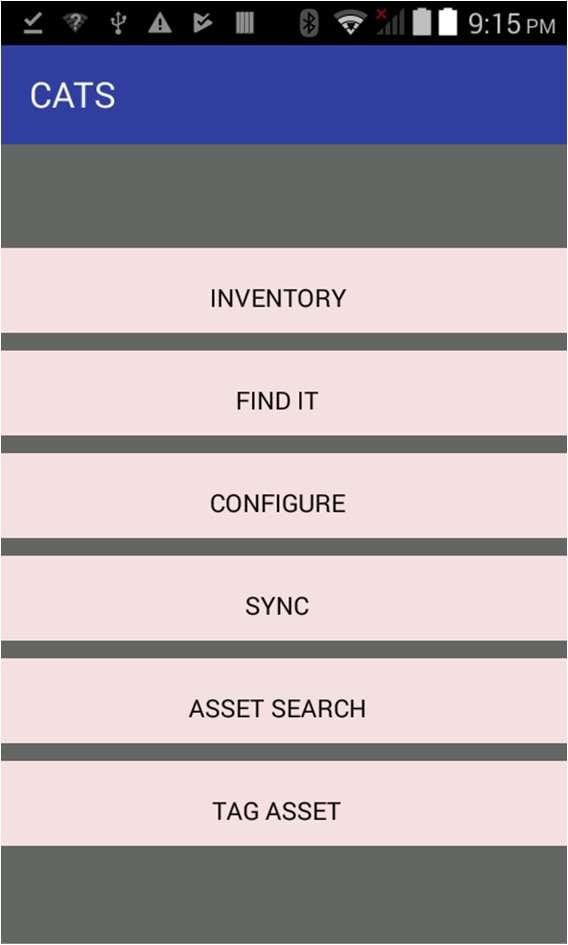

*Client Testimonial: We divided our building into sections with a few rooms in each section. I use our asset tracking solution to inventory the sections of our office each week, which captures a last known location for each document. When trying to locate a file, I go to our asset tracking software to find the last known location and start with that section first. The good thing about CATS is the Geiger counter feature. If the reader beeps, I know the files is in that area and then follow the increased beeping to its precise location. – Case Manager at Ohio Law Firm

When to use Barcodes or RFID

When choosing which technology to use, you need to determine what your critical assets are. What will shut down production if the item is missing? You also will want to look at your workflow to best understand what technology can help improve your process the most. It could be either Barcodes or RFID, or a happy marriage of both.

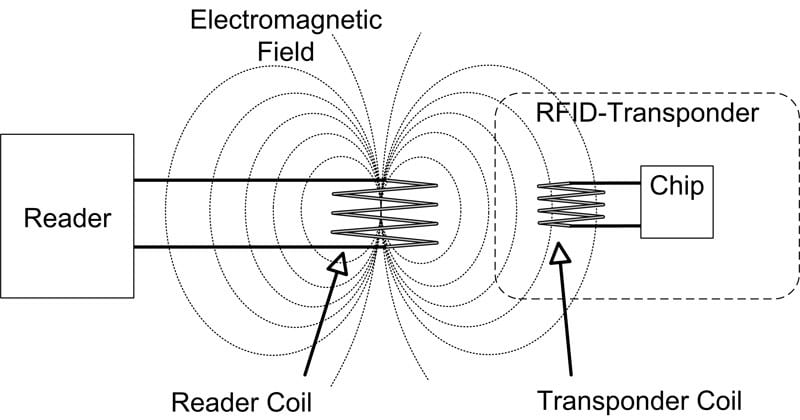

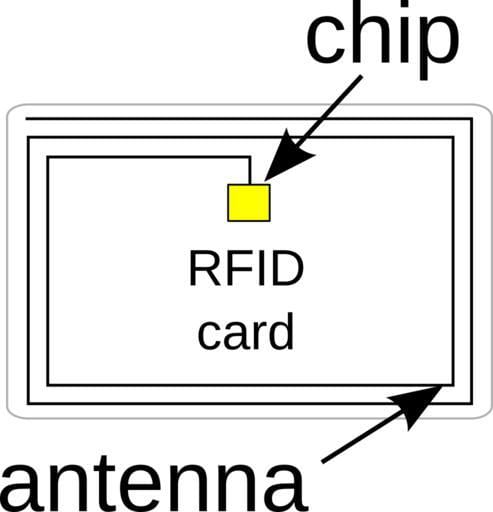

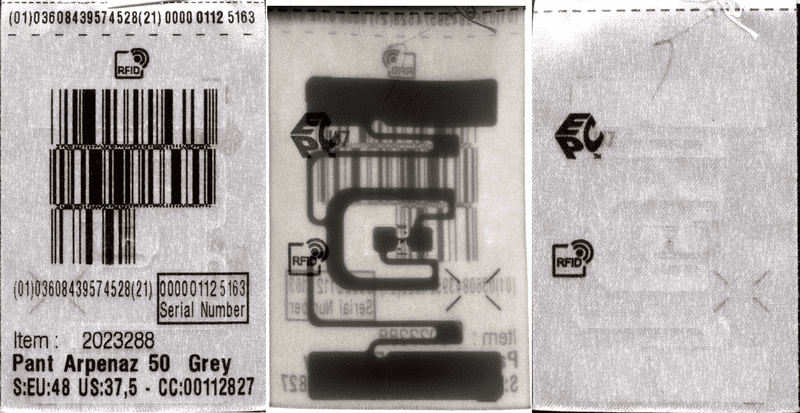

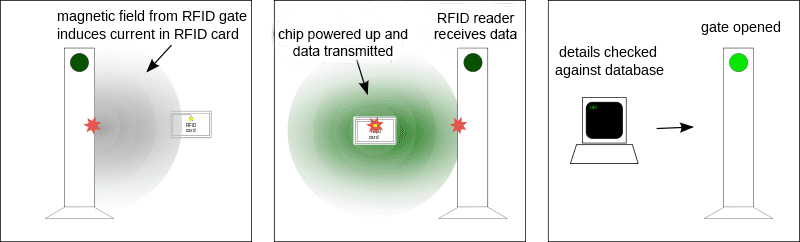

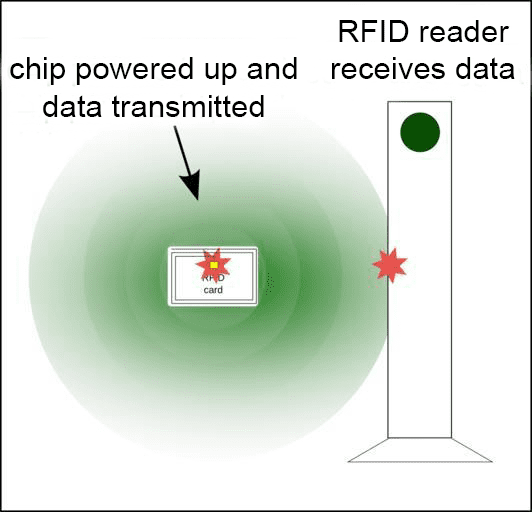

RFID handheld scanners or fixed antennas emit RF waves that can scan multiple items at one time. Additionally, RF can penetrate certain materials or move around objects to identify RFID tags you aren’t able to see. This saves time and can be automated. Barcodes require line of sight and can only scan one item at a time. The precision of barcodes will ensure you don’t accidentally scan something you don’t want.

Barcodes have been more popular in the past because it has been a historically less expensive option than RFID. The cost of RFID has gone down a lot recently, but Barcodes are still the best way to track less expensive assets. For example, grocery store products like milk cartons are high volume, low cost items and it would be better to utilize a less expensive technology to track them.

Automation and technology provide advantages but require an investment. There is a sweet spot between investing in automation and technology versus continuing with manual processes. You need to analyze your operations to calculate which one provides the best ROI for your workflow and organization.

Learn more in this Podcast with BlueStar.

If you have more questions or would like to further discuss your unique challenges, please schedule an appointment.